Description

Optimized starting and operating performance

- The metal spiral membrane in the carburetor allows the vibratory rammer to operate with low-grade fuel.

- Optimized fuelling makes the vibratory rammer resistant to an excessively rich oil and gasoline mixture ratio.

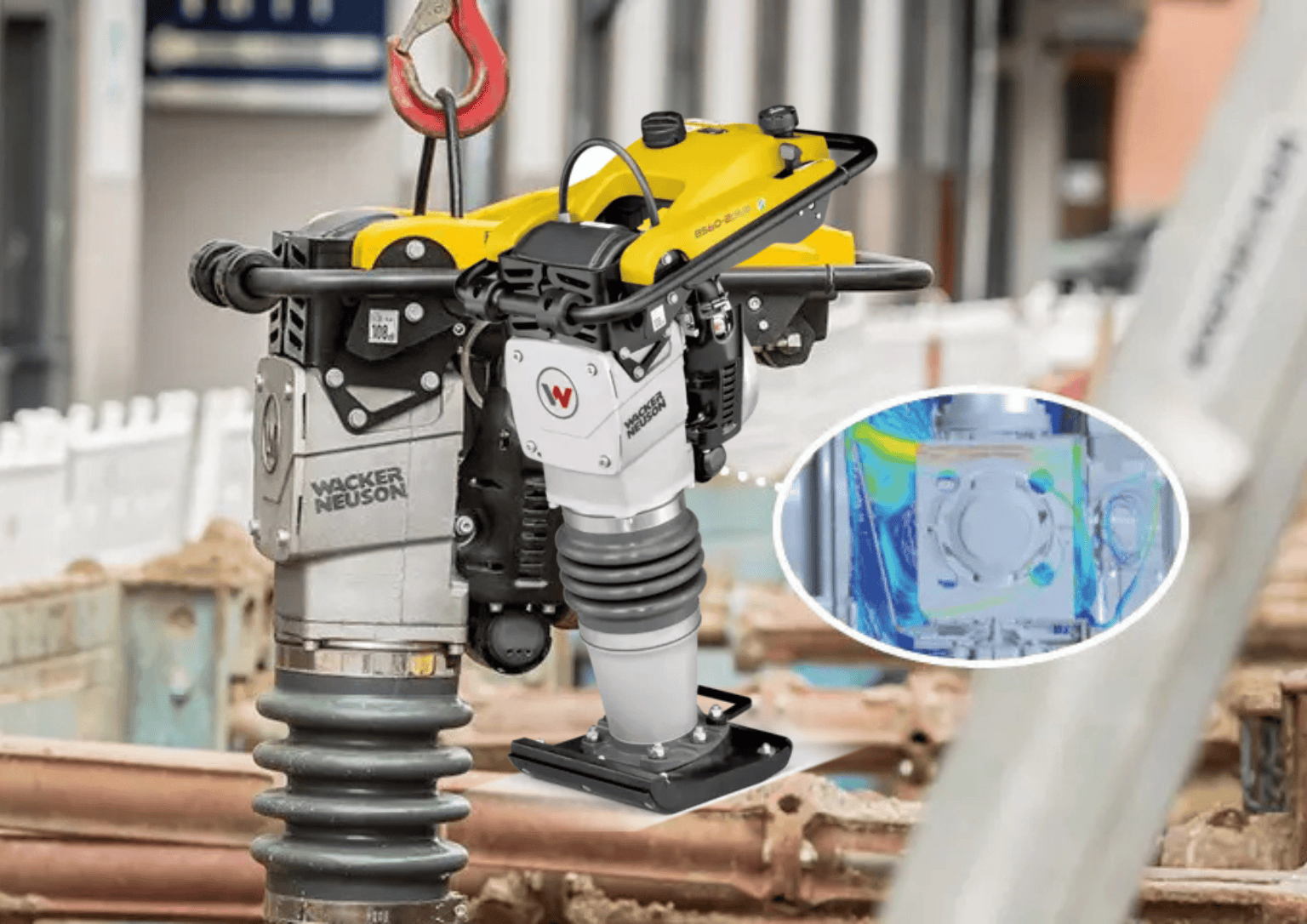

Optimized thermal management

- The vibratory rammer’s thermal management has been significantly improved by optimized cooling air flow. As a result, the vibratory rammer remains efficient even at very high outside temperatures.

Individual setting of the carburettor

- Since the carburettor is not adjusted until the engine is installed in the vibratory rammer, it offers an optimum ratio of power, fuel consumption, and low emissions.

2-stroke engine

- The 2-stroke engine is very sturdy and was developed specially by Wacker Neuson for the tough construction applications of vibratory rammers. The simple engine design makes maintenance easy and saves replacement part costs.

- Even in a tilted position, the 2-stroke engine is fully functional. This way, the engine can also be started without problems if the vibratory rammer has lain on its side.

Just one lever for starting, idling and stopping

- The vibratory rammer can be operated very comfortably using just one lever. The fuel cock is integrated in the lever. The choke is automatically deactivated at full throttle.